Alumatiq Case Study

What

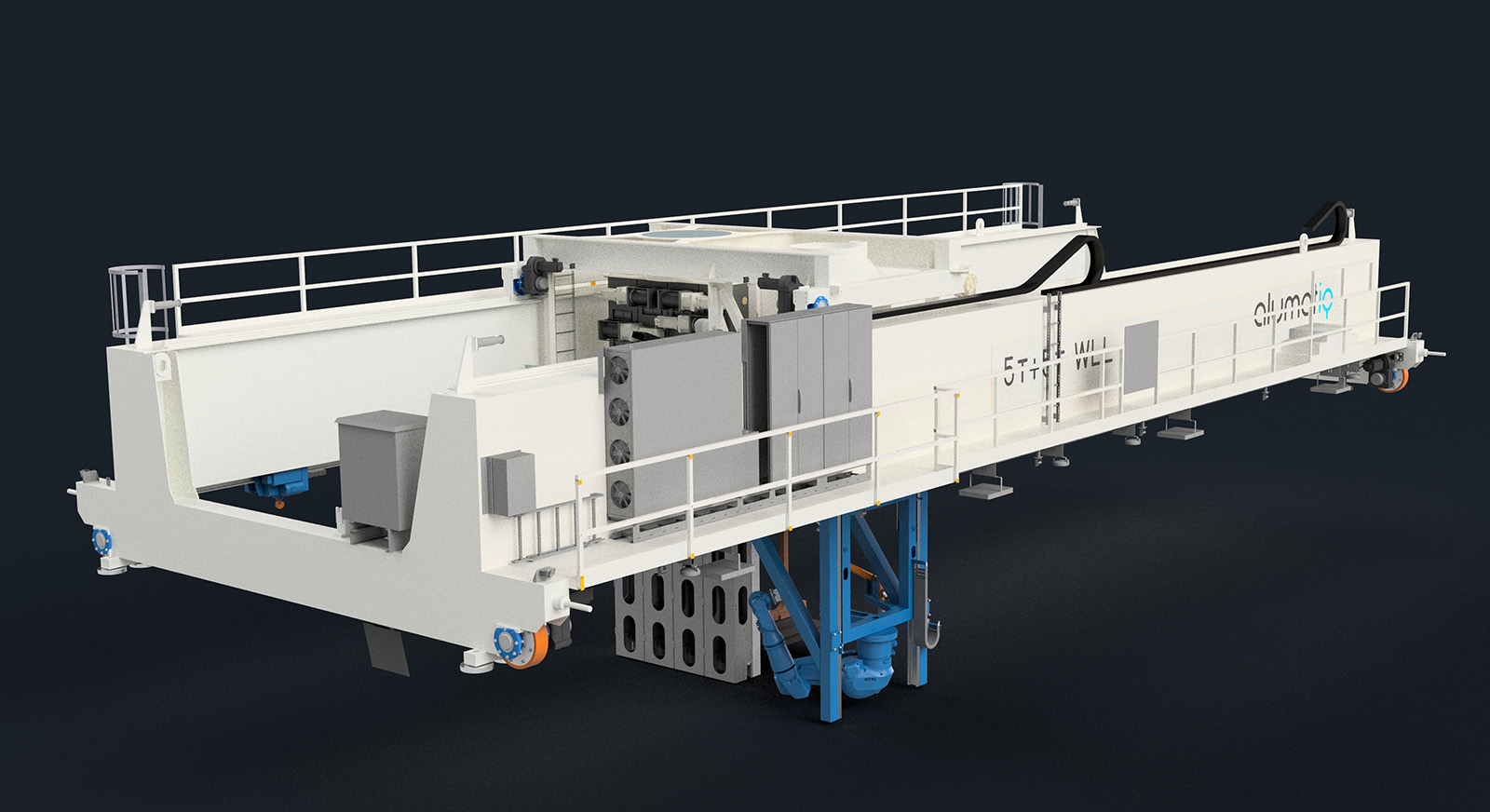

Anode Changing Robot for the Aluminum Industry

CoFounders role

CEO & Cofounder

AlumatIQ is an industrial spin-off from the metal industry cluster in Helgeland, Norway. The company is developing the world’s first anode changing robot, aimed at ensuring safer working conditions, reducing emissions, and enhancing profitability and efficiency for aluminum plants and cornerstone companies along the Norwegian coast.

Alumatiq is shaping the digital future

of aluminum smelting

The idea for the anode changing robot originated from Alcoa in Mosjøen, which envisioned automating the anode changing process. In 2017, Alcoa invited suppliers to present different solutions to this challenge, and the competition was won by Momek and Avanti Engineering, now part of Goodtech ASA, based in Mo i Rana.

In 2019, CoFounder was brought on board as the commercial and financial partner for the project. As a result, AlumatIQ AS was established in 2020 by Momek, Avanti, and CoFounder. Jan Biti from CoFounder took on the role of CEO, and a project team consisting of key personnel from Momek and Avanti was formed to further develop the solution. Frode Breimo was hired as the CTO in the fall of 2020.

The company is now in the process of piloting the world’s first anode changing robot and has garnered significant attention from potential customers and partners worldwide. Both Alcoa and Hydro Aluminium have become development partners in the project.

The project also has significant ripple effects on the supplier industry in Helgeland, contributing to substantial knowledge building.

CoFounder has accelerated the project and has been instrumental in securing approximately 60 million NOK in grants, loans, customer financing, and equity since 2020. Without CoFounder’s operational involvement, this project would likely not have come to fruition

— Vidar Olsen, Goodtech

Result

AlumatIQ has started the fabrication of the Robotic Anode Change System. The system is delivered with a new crane and will installed and tested in real industrial environment during 2023.